MACHINING

Machining is a group of processes used for removal of material to create shapes within desired tolerances. A&T offers a wide range of machining capabilities to our customers. We not only machine the castings, forgings and plastics that we manufacture, but we also supply machined fabrications and parts from bar stock or plate. In addition to the supplying of finished machined parts, we also provide these parts as subassemblies and can provide a finished turnkey solution as far down the value stream as the customer desires. This may include painting, plating, packaging and logistics management.

Machining is a group of processes used for removal of material to create shapes within desired tolerances. A&T offers a wide range of machining capabilities to our customers. We not only machine the castings, forgings and plastics that we manufacture, but we also supply machined fabrications and parts from bar stock or plate. In addition to the supplying of finished machined parts, we also provide these parts as subassemblies and can provide a finished turnkey solution as far down the value stream as the customer desires. This may include painting, plating, packaging and logistics management.

We work closely with our customers and subcontractors on part design, tooling and quality requirements on each project to minimize setup costs. This also aids significantly with progressing quickly through the first article sampling process and into production. Another service we offer is our ability to provide rapid prototypes to prove out designs before expensive tooling is purchased.

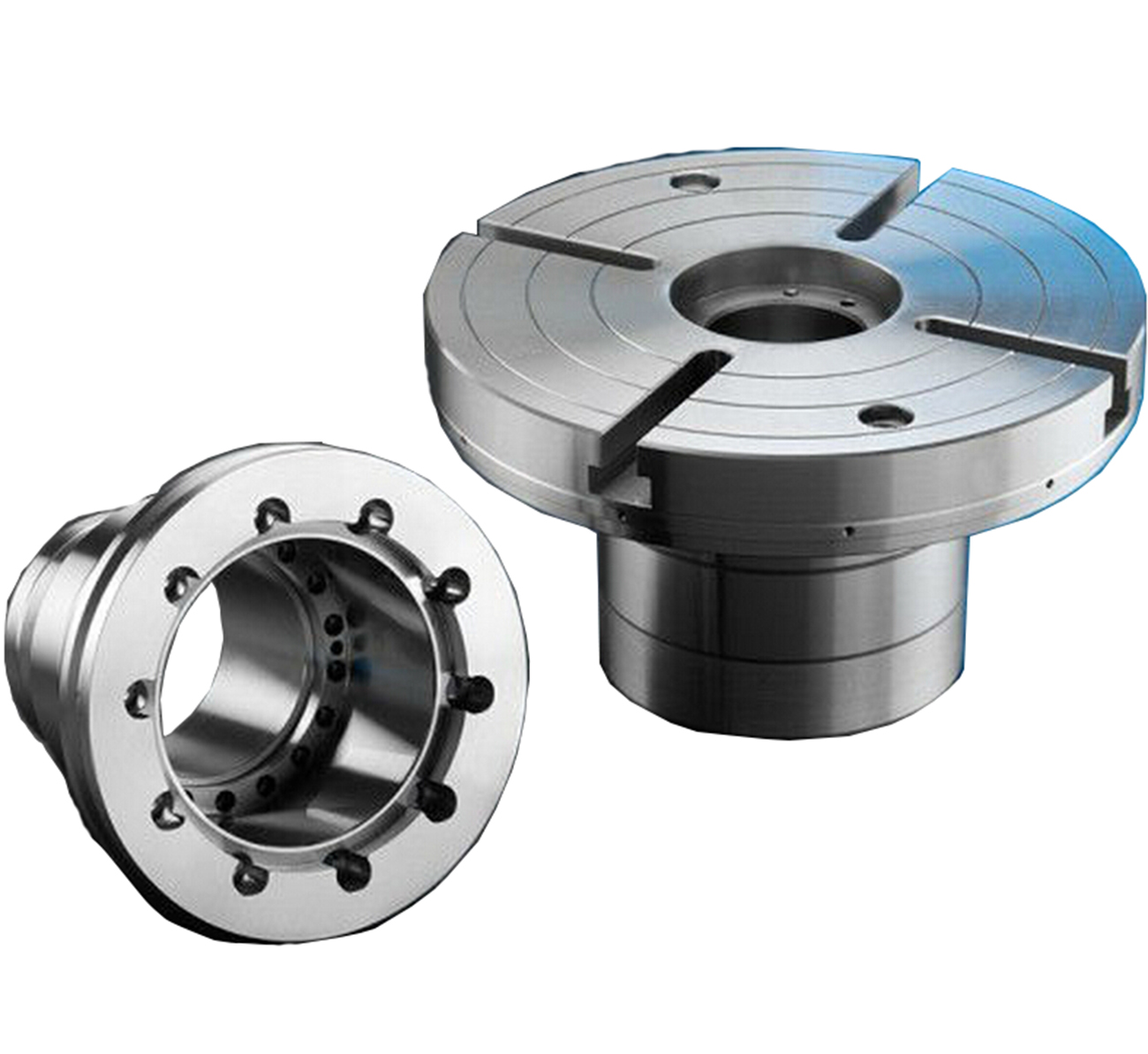

Machining capabilities include a complete range of processes:

Computer Numeric Control (CNC) — Machine equipment that is programmable for repeatability of shape and tolerance. Ideal for higher volume or complex parts and for utilization of customer-supplied solid models.

Grinding & Honing — Utilization of abrasives to develop the combination of a desired surface finish and precise tolerances. Primarily used to achieve flatness or cylindrical control in surface-to-surface mating components.

Gear & Spline Cutting — Gears are designed and manufactured to transmit torque or energy from one rotating shaft to another and can be supplied in varying tooth designs and profiles. Splines are utilized for positioning or locking parts to a shaft to prevent slippage under extreme torque applications.

Broaching — Incremental stock removal used in cases where typical machining is not practical due to feature configuration.

Electrical Discharge Machining (EDM) — Method in which material is burned off by use of a consumable carbon electrode. Ideal for cutting intricate shapes into hardened materials without the need for additional or secondary heat treatment.

Gun Drilling — Deep-depth drilling utilizing specialized tools that are capable of lubricating through an internal channel while in use. Allows for very large depth-to-diameter ratios.

Manual — Utilized as a low-volume, low-cost alternative to typical machining applications such as milling, drilling or grinding.

Chemical Milling — Precision material removal that is controlled by exposure time to a chemical etchant.

Prototypes — Initial parts produced to verify component design during research and development stage, which can provide critical information prior to investing in production tooling. Prototypes can be machined directly out of plastic, metal or wood, or made by using processes such as stereolithography (SLA) or selective laser sintering (SLS).

A&T offers customer solutions to real-world issues such as small-quantity order requirements or guaranteed on-time delivery. This is typically achieved with Kanban or customized stocking/inventory arrangements, resulting in cost savings, reduced warehouse requirements and delivery in days rather than weeks.

Our experience also extends into the verification of machined components. Working with our subcontractors, critical surfaces can be measured and documented using precise and repeatable processes. Measuring techniques can range from surface plate/height gauges to laser scanning. For ongoing production evaluation, specialized gauging can be developed depending on customer requirements.